EEDI/EEXI

Introduction

Limiting the volume of CO2 in vessel emissions is fundamental to the decarbonization of the maritime industry. VesselsValue employs the expertise of its analysts and researchers, supported by experienced industry experts, to deliver intelligence, transparency and clarity on Energy Efficiency Indices.

The International Maritime Organization (IMO) plans to reduce the carbon intensity of the Maritime industry by 40% (compared to 2008 levels) by 2030, as part of its long term commitment to decarbonize shipping. This enormous challenge begins with limiting the amount of carbon dioxide (CO2) present in vessel emissions. EEDI/EEXI is the IMO’s first attempt at such limiting.

EEDI was first introduced by a regulation drawn up by the International Convention for the Prevention of Pollution from Ships (MARPOL) and made mandatory for all ships at MEPC 62 (Marine Environment Protection Committee), held in July 2011. This was the first legally binding climate change treaty since the Kyoto Protocol. Proposals for EEXI, EEDI’s counterpart for existing vessels, were introduced at MEPC 75 in November 2020 and adopted at MEPC 76 in June 2021.

EEDI came into force on the 1st January 2013 and applies to all newbuild vessels above 400 gross tonnage (GT). EEXI is a similar index applying to all existing vessels above 400 GT and coming into force on the 1st January 2023. Both indices are technical as opposed to operational, and therefore cannot be altered without making physical adjustments to the vessel in question.

Description

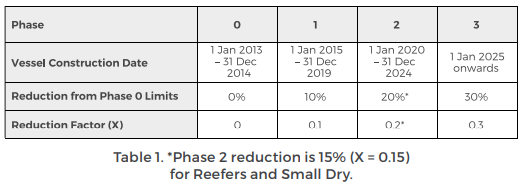

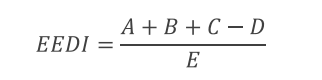

EEDI stands for Energy Efficiency Design Index. It is a measure of the energy efficiency of a vessel’s design and is calculated using a lengthy formula which takes this basic form:

EEDI calculation

EEDI applies to new vessels and has units of grams of CO2 emitted per ton of capacity per nautical mile (g CO2/t nm). In other words, it models the amount of CO2 a vessel would emit moving one ton of cargo capacity by one mile. A vessel’s EEDI will depend on many factors, including its design and technical specifications.

EEXI stands for Energy Efficiency Existing Ship Index and is applied retroactively to existing vessels. It is calculated using the same formula as EEDI, with minor amendments to deal with the unavailability of certain technical data for older vessels.

Limits on CO2 emission

EEDI Limits

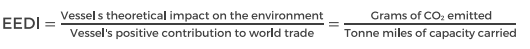

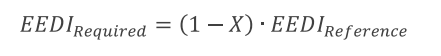

For a vessel to be compliant with IMO regulations, it must have an EEDI value (‘Attained’ value) under a certain limit (‘Required’ value). Required EEDI is generated using a ‘Reference EEDI’, which depends on the vessel’s type and deadweight. Required values depend on the vessel’s construction date and are being lowered, in phases, from their initial 2013 values. Phases run from Phase 0 to Phase 3, as shown in Table 1:

Table 1. *Phase 2 reduction is 15% (X =0.15) for Reefers and Small Dry.

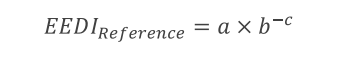

A breakdown of VesselsValue’s exact methodology regarding the allocation of phases can be found in Appendix i. The Reference EEDI is calculated by a formula provided by the IMO and is a function of deadweight ton (DWT)

EEDI Reference methodology

where the parameters a, b, and c are based on vessel type and provided by MEPC documentation. The table containing these parameters is shown in Appendix ii.

The Required EEDI is given by

EEDI Required methodology

where X is the reduction factor found in Table 1.

The following graph is a plot of the Required EEDI against DWT for a Bulker:

Figure 1. Required EEDI as a function of deadweight tonnage for all phases of the regulation

For vessels between 4,000 and 20,000 DWT, the reduction is a linear function of DWT , interpolating between 0% reduction and the maximum reduction of that phase, e.g., interpolating between 0 and 20% for Phase 2.

EEXI Limits

EEXI limits are treated slightly differently. Whilst the Required values are still calculated from the same Reference curve, the percentage reduction does not decrease with ‘phases’ but with DWT. The parameters are provided by the IMO and reproduced in Appendix iii.

As with EEDI, the formula for Required EEXI takes the form

where Y is the reduction factor provided in Appendix iii.

Compliance

In some instances, both Required EEDI and EEXI will apply to a vessel. To ensure that the vessel’s compliance or non-compliance is always reported accurately, the required values and the degree of compliance / noncompliance will be calculated and displayed separately for both EEDI and EEXI. This approach reflects regulations 22, 23 and 25 of MARPOL Annex VI found in MEPC 76.3 Amendments.

For brevity, the full EEDI equation has been shortened to the following form:

Shortened EEDI equation

This formula is based on simple principles which can be seen more clearly when broken down into its constituent terms. The full equation can be found in Appendix vi.

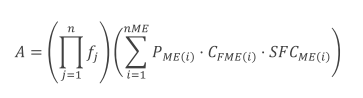

A. Main engine emissions

Expected CO2 emission from the main engines.

Calculation for expected CO2 emission from the main engine

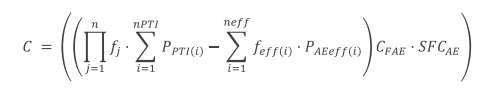

B. Auxiliary engine emissions

Expected CO2 emission from the auxiliary engines.

Calculation for expected CO2 emission from the auxiliary engines

C. Shaft generator/motor emission

Expected CO2 emission from shaft generators and motors.

Calculation for expected CO2 emission from the shaft generators and motors

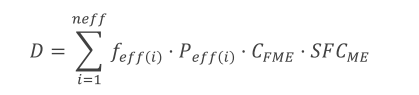

D. Efficient Technology Contribution

Expected CO2 emissions reduced due to the presence of any ‘innovative technologies for mechanical energy efficiency’, for example a sail and kite propulsion system.

Calculation for expected CO2 emissions being reduced by innovative technologies

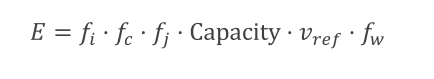

E. Work done by the vessel

Total cargo capacity of the ship multiplied by its reference speed, as well as other corrective coefficients.

Calculation for total cargo capacity of the ship multiplied by it’s reference speed, as well as other corrective coefficients

Parameters

The inputs used by VesselsValue are detailed below and are a combination of vessel specifications and ‘corrective factors’ found using IMO guidelines.

Main Engine Power (PME) [kW]

This corresponds to 75% of the rated installed power (MCR) of the main engine. When engine power limitation is employed, the lower of 83% of the limited power and 75% of the installed power is used in the EEXI calculation, pursuant to guidelines in MEPC 76. VesselsValue collects engine data from a variety of official sources. For vessels where reported data are unavailable, estimated values based on vessel type and size are used.

Main Engine Fuel Coefficient (CFME)

This parameter is a non dimensional conversion factor between fuel consumption and CO2 emissions. VesselsValue uses an estimated figure supplied by the IMO guidelines.

Main Engine Specific Fuel Oil Consumption (SFCME) [g/kWh]

The mass of fuel consumed in one hour to produce one kilowatt brake power. The SFC values provided by the engine manufacturers were used where available and the IMO approved default value of 190 g/kWh is used for engines fitted on existing vessels where data are not available.

For engines fitted on vessels under construction where SFC data are not available, the modelled value of 165 g/kWh was used, based on the figures in the IMO Fourth Greenhouse Gas study.

Auxiliary Engine Power (PAE) [kW]

This figure uses the IMO guidelines and depends on the rated installed power (maximum continuous rating or MCR) of a ship:

For vessels with MCR < 10,000 kW,

Calculation for vessels with MCR < 10,000 kW

For vessels with MCR ≥ 10,000 kW,

Calculation for vessels with MCR ≥ 10,000 kW

Auxiliary Engine Fuel Coefficient (CFAE)

This parameter is a non dimensional conversion factor between fuel consumption and CO2 emissions. VesselsValue uses an estimated figure supplied by the IMO guidelines.

Auxiliary Engine Specific Fuel Consumption (SFCAE) [g/kWh]

The mass of fuel consumed in one hour to produce one kilowatt brake power. The SFC values provided by the engine manufacturers were used where available and the IMO approved default value of 215 g/kWh is used for engines where data is not available.

Ice class power correction factor (fj)

A dimensionless coefficient adjusting the engine power based on the vessel’s ice class. Presently implemented as per MEPC 66 guidelines.

Capacity [DWT, GT]

‘Capacity’ is taken as DWT for all vessel types, save from two exceptions:

Containers use 70% of DWT

Passenger vessels use GT

Reference Speed (Vref) [knots]

VesselsValue calculates reference speed based on guidelines provided at MEPC 76. This is derived from a standard formula to ensure all vessels are comparable. This is detailed in Appendix iv.