IMOS - Shuttle Tanker Workflow

Note: Configuration flag CFGEnableShuttleFreightInvoicing must be enabled.

Part of the crude industry, shuttle tankers transport oil from offshore fields as an alternative to pipelines. They have unique machinery that enables them to connect with offshore field berths (pipes underneath the vessel).

In the Veson IMOS Platform, the following workflow enables you to manage shuttle tanker contracts end-to-end:

Setup

To set up the shuttle tanker workflow, do the following:

Create shuttle tanker vessels (Vessel Type T).

Create rules to define return (theoretical) times/rates and bunker consumption, which are used to calculate shuttle tanker freight.

With the help of a Veson Nautical consultant, set up Business Rules for:

Shuttle tanker freight: Source FINV, RINV, or TINV and Code CFRTS.

Volatile organic consumption (VOC): Source FINV, RINV, or TINV and Code VOCBC.

Shuttle tanker off hire: Source STOH and Code STOHD.

Creating Contracts Using Freight Type S

Shuttle tanker contracts are agreed-upon yearly, and freight is calculated based on actual and return hire and bunkers.

When creating Cargo COA, VC In COA, Cargo, or VC In contracts for shuttle tankers, charterers must set Freight Type to S (Shuttle Tanker). The Shuttle Freight Breakdown form appears, which shows the components of shuttle tanker freight.

Managing Shuttle Tanker Voyages

Individual shuttle tanker voyages typically are short (no more than 4–6 days). The vessel loads offshore and then leaves the field to discharge at an onshore receiver in port.

Operators can use the standard workflow for managing a voyage with the following modifications.

VOC Reporting

VOC refers to specialized onboard machinery that cleans the fumes from the burnt bunkers and also conserves some bunkers. VOC reporting may be required, depending on your shuttle tanker voyage route.

To report on VOC:

Enter VOC Consumption on in-port Activity Reports for shuttle tanker voyages (on the Extra Information for Report form).

Create a report in the Report Designer that includes VOC from the Activity Report Bunker Detail table.

SPOT and RELT Bunker Tracking

The Shuttle Tanker Workflow enables you to manage Initial Bunkers, Bunker Liftings, ROBs on Port Activities and Activity Reports, and Event ROBs for SPOT and RELT voyages.

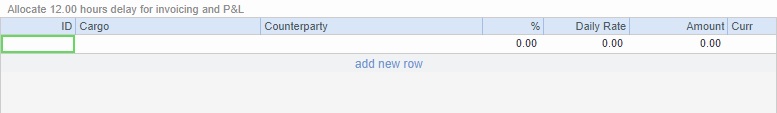

Delay Cost Allocation

On the Extra Delay Costs form, a new grid enables you to allocate delay costs to cargoes with Freight Type S:

Voyage P&L Impact

The following shuttle tanker–specific items appear on the Voyage P&L:

Actual and return hire

Actual and return bunkers

VOC cost or savings

Invoicing Shuttle Tanker Freight

Accountants can use the standard workflow for creating, posting, and approving a Freight Invoice with the following modifications.

VOC Deduction

VOC is deducted from shuttle tanker Freight Invoices, calculated as:

VOC Consumption Price = the FIFO price according to either:

ROBs at the NR Port Activity

If there is no NR activity, the price for ROBs at arrival

VOC Consumption Value = Quantity × VOC Consumption Price

Time and Bunkers Statement

The Time and Bunkers Statement report displays the breakdown of hire and bunker calculations, delays, and VOC for a shuttle tanker Freight Invoice.

To run the report, on the Freight Invoice, click